About

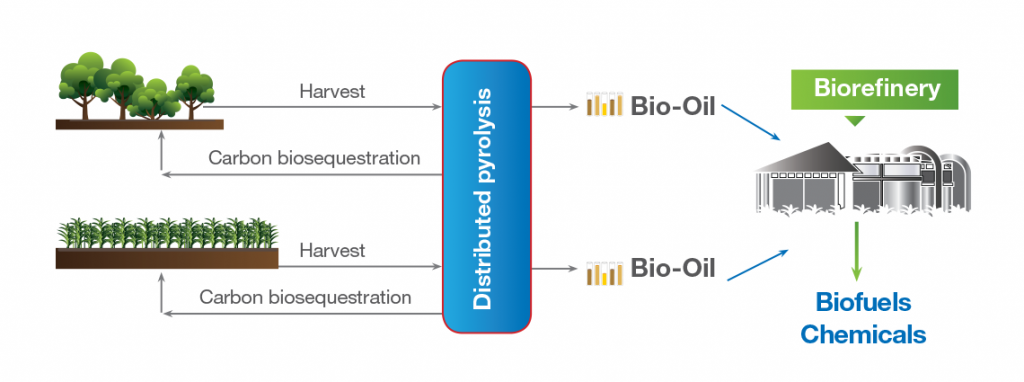

Renergi has demonstratied a two-step pyrolysis – biorefinery technology for the production of partially refined bio-fuels, advanced drop-in bio-fuels and chemicals.

With funding from ARENA over two R&D phases – Sustainable Production of Transport Biofuels between 2009 and 2012 and Low Emission Biofuel Technology between 2014 and 2019 – Renergi has successfully developed and demonstrated our innovative Biorefinery Technology.

Biomass is pyrolysed in distributed pyrolysers using Renergi’s grinding pyrolysis technology. The bio-oil is then collected for refining to produce advanced drop-in biofuels and chemicals. The key innovation of our biorefining technology is the hydrotreatment of bio-oil. A novel hydrotreatment reactor configuration has been developed.

The key feature of Renergi’s hydrotreatment reactor configuration is its ability to reduce coke formation, which is the single biggest problem facing the world’s efforts in developing an effective hydrotreating technology for bio-oil. Using commercial non-noble metal catalysts, Renergi / Curtin researchers have demonstrated the feasibility to produce biofuel that is miscible with petrol or diesel in any proportion.

You can read more about the project R&D of this technology here.

Environmental Impact

Renergi recognises the urgent need to transition to clean and renewable sources of energy to fuel our industrial processes and economy. Renergi diligently champions the pursuit of further developing our technology to be even more sustainable and even less energy intensive.

RELATED RECENT LITERATURE:

PATENTS:

- C.-Z. Li, R. Gunawan, M. Gholizadeh, W. Chaiwat. A method of hydrotreatment and a hydrotreatment system, PCT/AU2013/000825.

- C.-Z. Li, R. Gunawan, M. Z. Wang, S. Wang, L. Zhang. MD M Hasan and H. Wang, Method of and system for reactive distillation of bio-crudes. PCT/AU2019/050454.